|

Catalyst Services

The catalyst

is where oxidation takes place, stripping the process stream of unwanted

VOCs. So, of course, it is critical that the catalyst in your system

perform effectively at all times. A scheduled maintenance program with a

CSM field service engineer is the best way to ensure that the catalytic

oxidizer is operating at full strength.

|

|

|

|

|

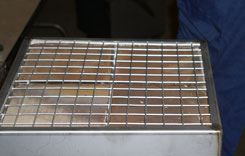

Ceramic Substrate

|

|

Cross Flow

|

|

|

|

|

|

|

|

|

|

VOC Catalyst

Module

|

|

CO Catalyst Ring

|

Catalyst Testing

On-site

visual inspection is the first step, followed by a series of tests to

determine the operating efficiency of the unit. This step is crucial in

helping determine how the unit is performing against design criteria. CSM

tests examine process performance as well as electrical and mechanical

operation. A visual inspection and catalyst activity test will reveal

whether the catalyst is being masked, which could lead to plugging that can

significantly affect the performance of the abatement system.

Catalyst Regeneraton

If

your catalyst is discovered to be masked, ship the catalyst modules to CSM

headquarters in Mountainside, N.J. There, they will be thoroughly washed

and cleaned, then sent back to your plant as quickly as possible.

Catalyst Leasing

While

your catalyst is being regenerated, or if the catalyst bed is no longer

working, simply lease a catalyst from CSM until yours is returned or a

replacement has been installed, thus ensuring that your plant will

experience only minimal downtime.

|